Navigate Your Construction Company Effectively with Top-Quality Aftermarket Construction Parts

Navigate Your Construction Company Effectively with Top-Quality Aftermarket Construction Parts

Blog Article

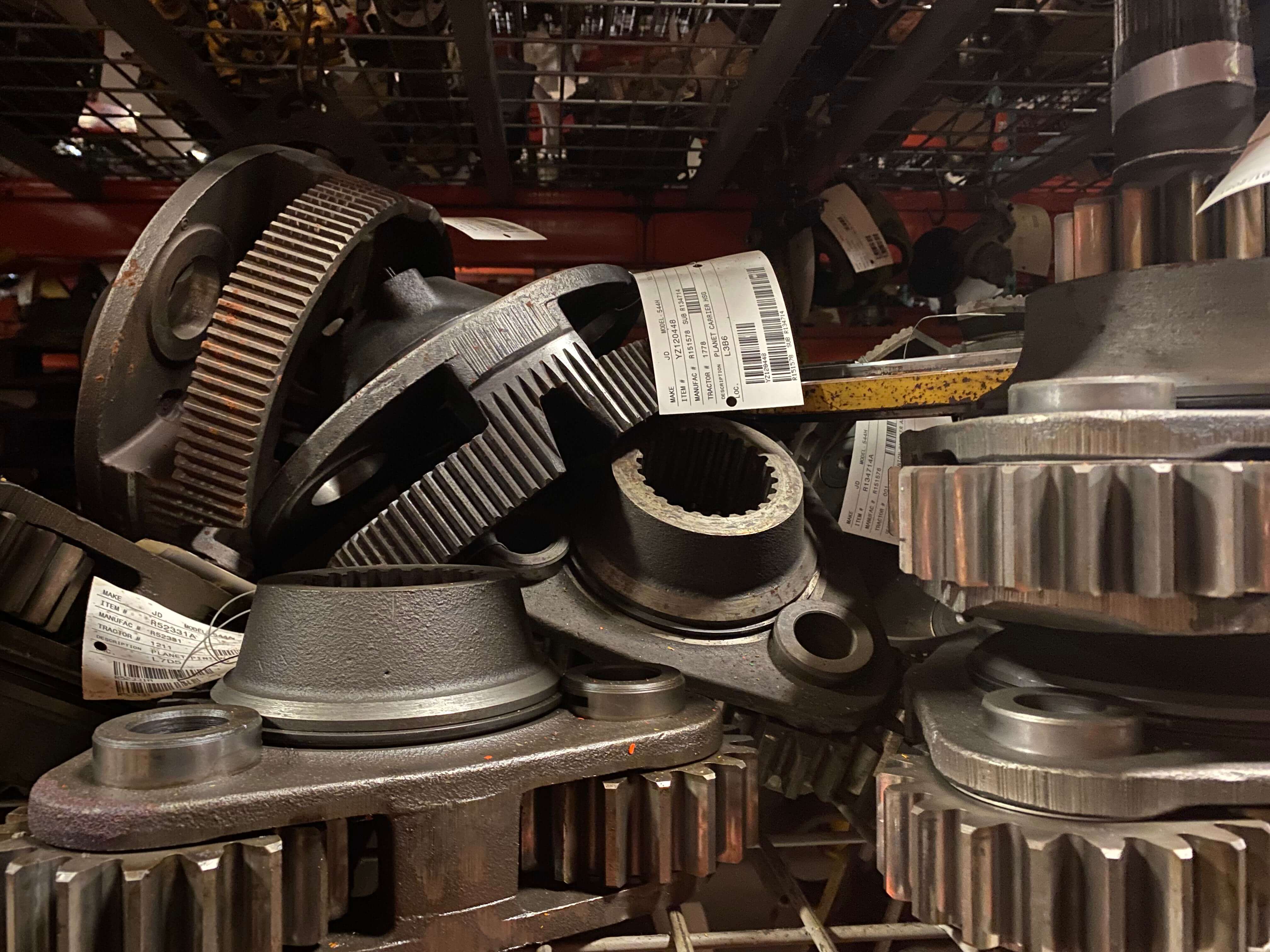

Boost Performance With Aftermarket Parts: an Overview for Heavy Machinery Owners

Advantages of Aftermarket Components

Proprietors of hefty machinery can enjoy various benefits by selecting aftermarket parts over original devices maker (OEM) parts. One of the main advantages is price financial savings. Aftermarket parts are commonly a lot more cost effective than OEM parts, allowing machinery owners to minimize maintenance and fixing prices without compromising on top quality. In addition, aftermarket components typically feature guarantees, ensuring that purchasers are secured in case of any type of defects or problems.

An additional benefit of aftermarket parts is the bigger choice readily available out there. Since aftermarket producers focus on producing details parts, machinery owners have access to a more comprehensive variety of options to fit their needs. This variety can result in improved efficiency and effectiveness of the equipment. Aftermarket components are known for their high quality and reliability, with many meeting or surpassing OEM requirements. aftermarket construction parts.

Finally, selecting aftermarket parts can additionally cause faster repair work and reduced downtime. With much easier availability and fast shipping options, machinery owners can obtain their equipment up and running once more promptly, minimizing disruptions to their procedures.

Selecting the Right Aftermarket Components

When thinking about aftermarket components for hefty equipment, it is necessary to focus on compatibility and top quality to ensure optimal performance and longevity of the devices. Picking the right aftermarket components can be an essential choice for heavy equipment proprietors as it directly impacts the effectiveness and reliability of their equipment.

Second of all, quality needs to never be compromised when selecting aftermarket components (aftermarket construction parts). Choosing top quality elements makes certain longevity, dependability, and total efficiency of the equipment. It is suggested to source aftermarket components from trusted producers or distributors understood for their top quality criteria

Additionally, considering aspects such as service warranties, customer reviews, and compatibility with existing systems can better assist in making the ideal choice. By prioritizing compatibility and high quality when selecting aftermarket components, hefty machinery owners can enhance the performance and durability of their tools.

Installment and Maintenance Tips

For reliable operation and longevity of hefty equipment, correct setup and normal upkeep are vital. When mounting aftermarket components, ensure that you thoroughly comply with the supplier's instructions to assure optimum performance. It is vital to use the right tools and techniques to avoid any damages during the installation procedure. Regular upkeep is crucial to maintain your machinery running smoothly. Develop a maintenance routine that consists of jobs such as inspecting fluid degrees, checking for damage, and cleaning elements (aftermarket construction parts). Immediately attend to any type of issues that arise to stop more damage and expensive repairs. Additionally, consider investing in training for your maintenance team to ensure they have the essential skills to determine and address prospective issues. By prioritizing setup and upkeep procedures, you can optimize the performance and life-span of your heavy equipment, ultimately conserving time and money over time.

Cost-Effectiveness of Aftermarket Components

Appropriate installation and normal maintenance are fundamental elements for heavy machinery owners intending to analyze the cost-effectiveness of aftermarket components for their equipment. While initial tools producer (OEM) components are understood for their quality, aftermarket parts offer a more economical remedy without compromising performance. The cost-effectiveness of aftermarket components becomes apparent in various ways. Firstly, aftermarket components are commonly extra budget-friendly ahead of time, enabling owners to accomplish financial savings on initial purchase prices. In addition, these parts usually give equivalent efficiency to OEM parts, guaranteeing that the equipment operates efficiently without the need for pricey substitutes. The availability of aftermarket components from a broad array of distributors advertises competition, leading to affordable prices and more price savings for owners. By very carefully evaluating the quality and compatibility of aftermarket parts with their equipment, owners can strike an equilibrium between cost-effectiveness and performance, ultimately maximizing the efficiency and longevity of their heavy devices.

Making The Most Of Efficiency With Aftermarket Upgrades

To content enhance functional efficiency and productivity, heavy machinery proprietors can successfully make best use of efficiency with tactical application of aftermarket upgrades. Aftermarket upgrades offer the possibility to customize hefty equipment to certain operational needs, causing boosted functionality and output. Upgrading parts such as engines, transmissions, hydraulic systems, and tracks can significantly improve the overall performance of the machinery.

Routinely assessing the efficiency of hefty equipment and recognizing areas where aftermarket upgrades can be valuable is crucial for maximizing performance. By buying high quality aftermarket components and upgrades, machinery owners can achieve greater levels of effectiveness, eventually leading to set you back savings and improved functional end results.

Conclusion

Finally, aftermarket components provide countless benefits for hefty machinery owners, including cost-effectiveness, boosted effectiveness, and modification alternatives. By selecting the right aftermarket components, following correct installation and maintenance procedures, and making best use of upgrades, heavy machinery proprietors can increase their devices's efficiency and durability. Purchasing aftermarket parts can eventually result in enhanced productivity and decreased downtime, making it a worthwhile consideration for owners looking to maximize their equipment procedures.

Owners of heavy machinery can appreciate countless advantages by choosing for aftermarket parts over original tools supplier (OEM) components. Aftermarket parts are generally more economical than OEM parts, permitting equipment owners to reduce upkeep and repair service costs without compromising visit this site on top quality. By very carefully assessing the quality and compatibility of aftermarket components with their machinery, proprietors can strike an equilibrium between cost-effectiveness and efficiency, eventually making the most of the efficiency and durability of their heavy tools.

In final thought, aftermarket components use numerous advantages for heavy equipment owners, consisting of cost-effectiveness, enhanced performance, and personalization options. By selecting the right aftermarket components, following appropriate installation and maintenance treatments, and optimizing upgrades, heavy machinery proprietors can increase their tools's performance and durability.

Report this page